TOWARD A SUCCESSFUL PET RECYCLING STREAM

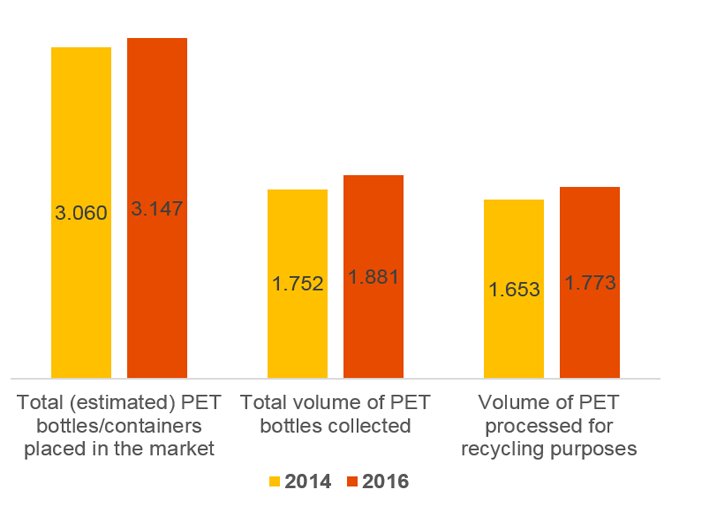

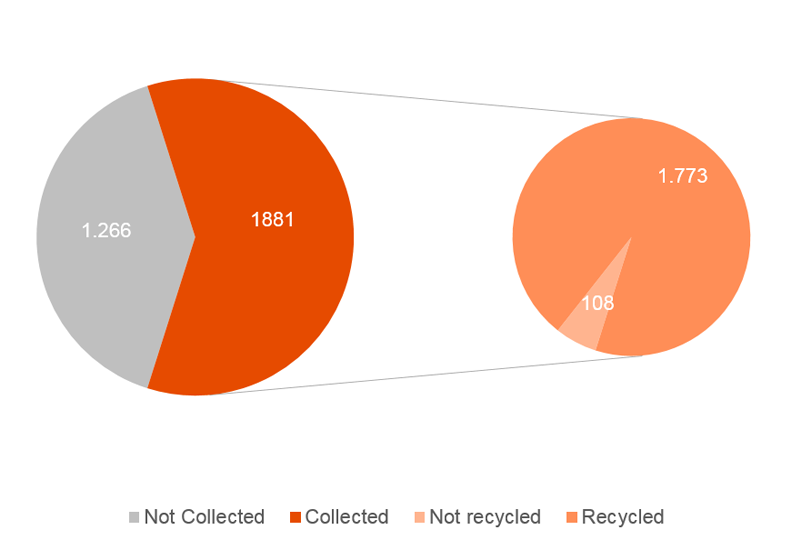

In 2016, the global production of PET was 50 million tonnes. Out of them, 617 billion units PET bottles were used to package food, beverage, home

and personal care products [1]. Figures from West Europe[2] show that actual volume of PET processed in that year for recycling purposes

reflected more than 56% of what produced – and approximately 95% of what collected. The major market for recycled PET remains sheet - 38%,

blow-moulding - 26%, fibre - just under 24% and strapping and other applications - just over 11%[3]. However, the great variance in the individual

country collection rates - with virtuous peaks of over 90% in Germany and Norway – demonstrates that there is still some work to be done, to fully

apply a circular economy approach to PET packaging. Still, we see increased commitments from brand owners towards recycled PET and

machines manufacturers are adjusting their equipment to higher rates recycled PET. Final objective is to keep resources in use for as long as

possible, extract the maximum value from them whilst in use, then recover and regenerate products and materials at the end of each service life.

This mission is imperative, considering that PET adoption in the food, beverage, home and personal care markets is projected to grow by 3% (2016-2020)[4].